20-30% Less Expensive

Trenchless rehabilitation is more cost effective than dig and replace methods. Our in-house developed and tested materials and liners have a 50-year design life, making it a better choice to repair aging infrastructure.

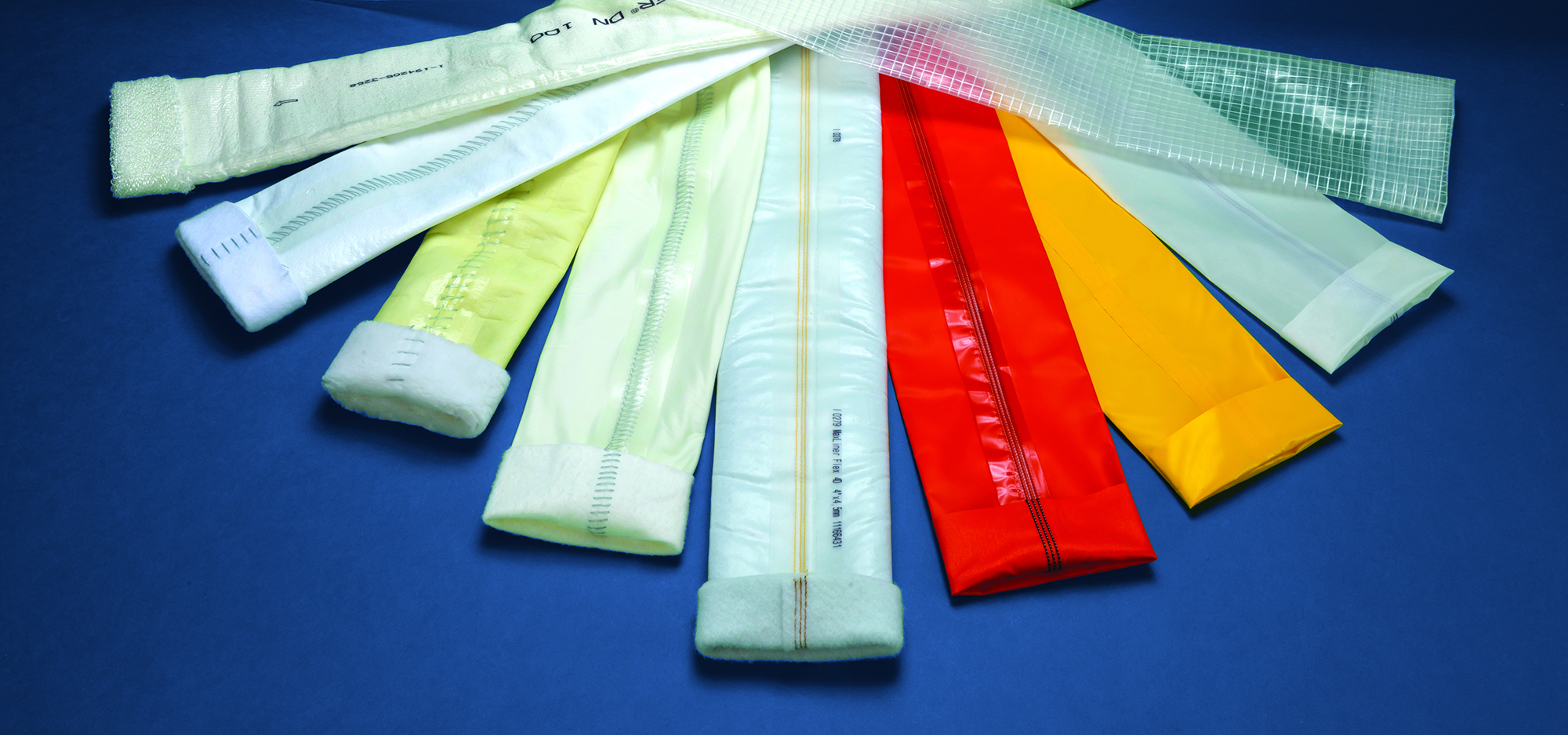

Backed by the Vortex family of companies, MaxLiner® liners and resins consumables are designed in collaboration with United Felts and Vortex Products divisions. As a pioneer in Cured-in-Place Pipe (CIPP) technology, United Felts produces the only liners in the market manufactured entirely in the U.S.A. – from raw material to finished product – under a rigorous 33-point quality control process. It is this attention to detail that allows us to deliver liner systems that set the standard for performance and reliability in small diameter rehabilitation.

Trenchless rehabilitation is widely accepted around the world as the preferred, cost-effective, and durable option in repairing aging infrastructure for both main line sewer systems and residential systems. MaxLiner has the most robust small diameter lining offering to address a broad range of challenges. This is underpinned by field service expertise, training, field support and business development support. A true partner.

Trenchless rehabilitation is more cost effective than dig and replace methods. Our in-house developed and tested materials and liners have a 50-year design life, making it a better choice to repair aging infrastructure.

Trenchless projects can be completed in a fraction of the time it takes to perform traditional excavation. This speed of completion minimizes inconvenience to home and business owners.

Trenchless technology often utilizes advanced materials and methods that can enhance the lifespan and durability of the rehabilitated pipes. These solutions can also improve the flow capacity and efficiency of the existing systems.

From supporting homeowner education, to project bidding, to installation and completion, and tools to help contrctors scale their business, MaxLiner partners with our customers to ensure your projects execute flawlessly while also supporting your business growth.

MaxLiner is part of the Vortex Company whose materials and liners are designed, developed and tested in house, unlike many providers. We were pioneers in the first CIPP liner manufacturing. From raw material to finished goods, we are committed to quality.

MaxLiner offers hands-on training in the field or at our Virginia headquarters, where contractors learn the full CIPP process in a simulated lab. We also provide tools to help you win more business including training on how to explain CIPP to homeowners, demonstrate its value, and bid projects that are both profitable and budget-conscious.

We empower our customers with extensive training and dedicated field support to ensure project success and business growth. Our hands-on programs, offered at our facilities or on-site, cover everything from material application and liner installation to equipment use and robotics. Beyond the job site, we help contractors sell to homeowners with tools, messaging, and strategies that build trust and drive demand. Our expert team is also available 24/7 for troubleshooting and guidance to keep your projects and your business moving forward.

Plumbing and drain cleaning professionals across the country are scaling their businesses with MaxLiner’s small diameter CIPP solutions. Our Installer Program gives you the tools to scale your business with exclusive training, ongoing field support, and guaranteed product access. As a MaxLiner CIPP Installer, you join a trusted network of contractors delivering high-quality CIPP installs with confidence and efficiency.

Opt-in to our newsletter full of best practice, guidance and MaxLiner deals.